CMP – GE

CEMENT PRODUCTION

EFFICIENCY IMPROVEMENT

The cement producers are expected to deliver superior performance while lower-ing production costs and minimizing their environmental footprint. Our CMP-GE series grinding aids are developed in order to make it easy to achieve these goals.

Our high quality product CMP-GE series shall provide solution of significantly improve the grinding efficiency, improve cement’s pack set and flow-ability of cement powder.

Using CMP-GE series additives and cement production best practices gleaned from our field experience, you can achieve lower water injection, less cement pre-hy-dration and therefore:

- Shorter initial and final setting time.

- Higher early and late strength.

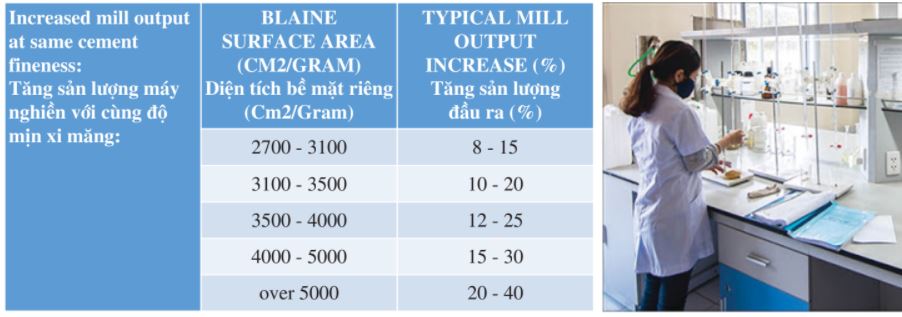

- Increased throughput.

- Lower energy consumption.

Usage

CMP-GE can be sprayed onto the clinker conveyor or directly into the ball mill. No need to add water to the ball mill system. An appropriate dosing system is required to ensure accurate and consistent dosing for maximum effectiveness.

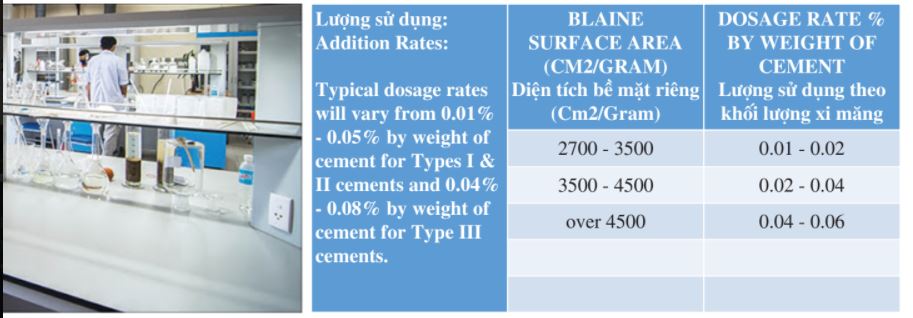

Dosage

Dosage of CMP-GE series is calculated base on grinding aids using amount to the weight of cement. Usability levels are optionally developed according to customer requirements, clinker type, mill system, site conditions as well as desired results.

điều kiện tại chỗ cũng như kết quả mong muốn.

Packaging

Packagin of CMP-GE series is selected by customer optionally as

following:

- Steel drum, plastic drum: 205Kg

- IBC tank 1000Kg.

- Truck and supplying pump.

Quality

CMP-GE series are controlled in accordance with ASTM C465.

Self - life

CMP-GE used within 12 months from the date of production with stored condition in a cool place at a temperature range from 5 - 39oC in a tightly sealed container.

Necessary notes

Refer to and follow the instructions in the Material Safety Data Sheet (MSDS) for more details on Health, Safety and Environmen-tal directives.